Compressor lubricants are critical to efficient operation

Most factories and manufacturing facilities use compressed gas systems for a variety of applications, and keeping these air compressors running is critical to keeping the entire operation running. Nearly all compressors require a form of lubricant to cool, seal or lubricate internal components. Proper lubrication will ensure that your equipment will continue operating, and the plant will avoid costly downtime and repairs. Proper lubrication also will help compressors run cooler and consume less electrical energy. It is simple: reduced friction = reduced heat = reduced energy consumption. Compressed air systems in most manufacturing plants consume a majority of the daily power requirements, so if you are looking for a continuous improvement project, reducing energy costs through better lubricant practices is a sure winner.

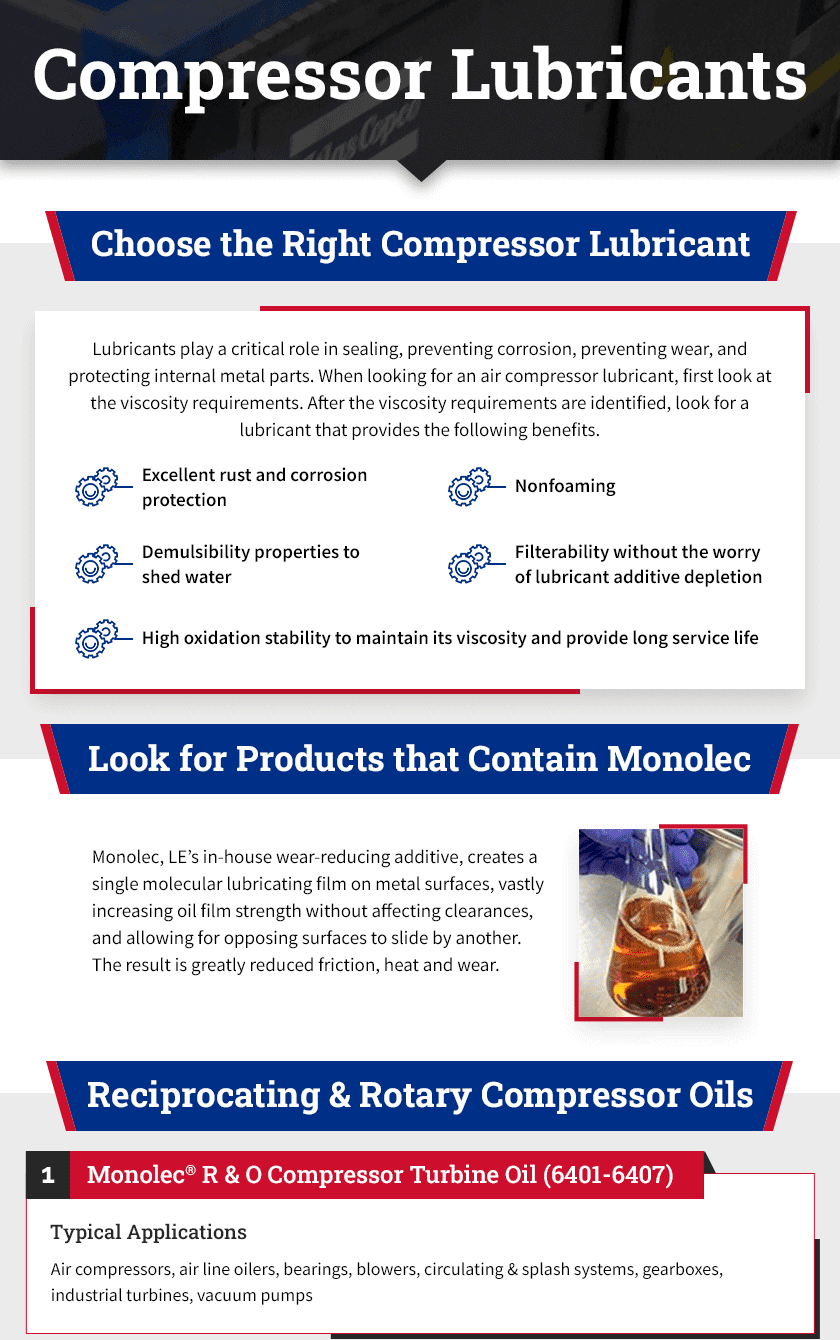

Choose the right compressor lubricant

Lubrication requirements vary considerably based on compressor type, the environment in which it is used, and the type of gas that is being compressed. Lubricant plays a critical role in sealing, preventing corrosion, preventing wear, and protecting internal metal parts. LE has the right lubricants for most compressor types, whether they are centrifugal compressors, reciprocating compressors, rotary screw compressors, rotary vane compressors or dry screw compressors.

When looking for an air compressor lubricant, first look at the viscosity requirements. After the viscosity requirements are identified, look for a lubricant that provides the following benefits.

- Excellent rust and corrosion protection

- High oxidation stability to maintain its viscosity and provide long service life

- Nonfoaming

- Demulsibility properties to shed water

- Filterability without the worry of lubricant additive depletion

Don’t shoot for the bottom of the barrel when it comes to operating specifications. Instead, look for lubricants that exceed specifications. In doing so, you will help your air compressor equipment last longer and run more efficiently.

Look for products that contain Monolec

Monolec, LE’s in-house wear-reducing additive, creates a single molecular lubricating film on metal surfaces, vastly increasing oil film strength without affecting clearances, and allowing for opposing surfaces to slide by another. The result is greatly reduced friction, heat and wear.Learn more about Monolec.

Reciprocating & Rotary Compressor Oils

Monolec® R & O Compressor Turbine Oil (6401-6407)

Monolec® R & O Compressor / Turbine Oil is a versatile, heavy-duty oil designed to prolong compressor equipment life by combating the effects of high temperatures, water, contaminants and heavy loads that accelerate wear. Available in seven different viscosity grades, it is ideally suited for use in all types of air compressors and oil circulating systems. This long-lasting, nonfoaming, turbine-quality oil provides peace of mind by ensuring that your equipment works when it is needed, whether you run it intermittently or continuously. With its superior resistance to heat, oxidation and moisture, Monolec R & O Compressor / Turbine Oil significantly outperforms ordinary commercial air compressor and turbine oils.

Typical Applications: Air compressors, air line oilers, bearings, blowers, circulating & splash systems, gearboxes, industrial turbines, vacuum pumps

Available ISO Viscosity Grades: 32 (6401), 46 (6402), 68 (6403), 100 (6404), 150 (6405), 220 (6406), 320 (6407)

Multilec® Industrial Oil (6801-6807)

Versatile multifunctional Multilec Industrial Oil provides superior long-term anti-wear protection in variety of compressor applications. It is heavy-duty oil designed to prolong equipment life by combating the effects of high temperatures, water, contaminants and heavy loads that accelerate wear. Available in seven different viscosity grades, this multipurpose lubricant is ideally suited for use in all types of air compressors, hydraulics, oil circulating systems, industrial turbines, and R & O industrial and gear applications.

Typical Applications: Air compressors, air line oilers, bearings, blowers, circulating & splash systems, cranes, gearboxes, hydraulics, industrial turbines, vacuum pumps

Available ISO Viscosity Grades: 32 (6801), 46 (6802), 68 (6803), 100 (6804), 150 (6805), 220 (6806), 320 (6807)

Monolec® Syn Industrial Oil (9032-9680)

Monolec Syn Industrial Oil is designed to prolong equipment life by combating the effects of high temperatures, contamination and loads that accelerate wear in compressors. It is a versatile synthetic lubricant that meets or exceeds the requirements of gearboxes, air compressors, vacuum pumps, hydraulic systems, and roll mill bearings found in the textile, plastic, rubber and paper industries. It is formulated with high-viscosity 100 percent synthetic base oil and a specially developed additive package for applications running at extreme temperatures. The additive package provides outstanding thermal stability and rust and oxidation resistance as well as wear resistance as pressures and temperatures rise. A foam suppressant completes the package. The base oil and additive formulation works synergistically to reduce wear, extend oil drain intervals, reduce oil consumption, and practically eliminate deposits and sludge formation, all while providing excellent compatibility with seals.

Typical Applications: Air compressors (reciprocating & rotary), bearings (oil-lubricated), chains (including dryer chains), gearboxes, hydraulic systems, vacuum pumps, worm Gears (9460 only). Also suitable for use as: circulating oil, AGMA R & O gear oil.

Available ISO Viscosity Grades: 32 (9032), 46 (9046), 68 (9068), 100 (9100), 150 (9150), 220 (9220), 320 (9320), 460 (9460) 680 (9680)

Centrifugal Compressor Oil

Endure™ Turbine Oil (6481-6482)

Endure™ Turbine Oil (6481-6482) features a unique blend of highly refined base oils and proprietary additive technology. This turbine quality oil can also be used in centrifugal compressor applications. Its advanced formula provides superior oxidative and thermal stability while preventing varnish and sludge formation on critical surfaces. Endure Turbine Oil ensures long-lasting, trouble-free performance in centrifugal compressors, minimizing unplanned outages and maximizing uptime.

Beneficial Qualities

- Exhibits superior oxidative and thermal stability for long-term performance

- Inhibits varnish, sludge and deposit formation

- Exhibits superior air release properties and suppresses foam

- Provides outstanding rust, corrosion and anti-wear protection

- Separates readily from water

- Is filterable for long-term oil cleanliness

Typical Applications: Gas Combustion turbines, Combined cycle turbines, Centrifugal compressors

Available ISO Viscosity Grades: 32 (6481), 46 (6482)

Monolec® Centrifugal Compressor Oil (6260)

A high quality compressor oil designed specifically for use in centrifugal air compressors. Formulated with highly refined select paraffinic base stocks synergistically blended with additives that offer excellent corrosion protection, superior thermal stability, good water separation, antifoaming performance and oxidation resistance.

Typical Applications: This product was formulated to meet the lubricating oil requirements for Ingersoll Rand Centac Centrifugal Compressors. As such, it is also acceptable for use in centrifugal compressors built by other manufacturers that specify a premium ISO 32 viscosity R & O mineral oil lubricant. It is not suitable for use in Ingersoll-Rand X-FLOs, OCV/3CH, 6 CM, or 1CD 13 (NXP13 portable) units.

Available ISO Viscosity Grades: 32 (6260)

Food Grade Compressor Oils

LE manufactures a full line of NSF H1 registered food grade oils and greases for a variety of industrial applications, including the following food grade oils recommended for use in compressors. For more information about these and our other LE food grade lubricants, go here.

H1 Quinplex® Synthetic Food Grade Oil (4032-4068)

H1 Quinplex Synthetic Food Grade Oil is an NSF H1 registered synthetic food grade oil formulated for use in food processing and other sensitive environments where superior anti-wear, rust and oxidation resistant properties are required. It clings to equipment and provides reliable water-resistant protection from oxidation, rust and wear. Featuring 100 percent synthetic base oil, H1 Quinplex Synthetic Food Grade Oil has excellent load-carrying abilities, can be used in low-temperature applications, and contain Quinplex, LE’s proprietary impact-resistant additive.

Typical Applications: Bearings, bushings, slides, chains, compressors (including rotary screw air), vacuum pumps and hydraulics used in: animal feed preparation, aluminum/metallic foil and package manufacturing, food processing, paper-making machinery, and textile machinery

Available ISO Viscosity Grades: 32 (4032), 46 (4046), 68 (4068)

H1 Quinplex® White Oil (4010-4040)

H1 Quinplex White Oil is an extremely pure, nonstaining, odorless, tasteless, translucent and non-irritating lubricant that can be used with confidence where incidental food contact or staining can occur. It provides superior anti-wear performance that many white oils on the market do not offer.

Typical Applications: Lubricant and rust preventative for machinery and other equipment in food processing and animal feed preparation; lubricant for drawing, stamping, forming and rolling metallic foil and packages used in food packaging; machinery lubricant for textile and paper industries; lubricant for use in bearings, bushings, slides, chains, compressors, vacuum pumps and hydraulics

Available ISO Viscosity Grades: 46 (4010), 68 (4020), 100 (4030), 150 (4040)

For more information about LE’s compressor oils, please Contact us today.